In modern spraying operations, accuracy starts long before the boom ever unfolds in the field. One often overlooked, but critically important practice is chemical recirculation inside the tote. For growers, custom applicators, and ag retailers alike, recirculating chemicals prior to loading helps ensure consistent product concentration, accurate application rates, and smooth system performance.

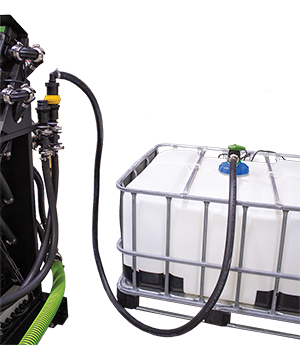

That’s why Dura Products now offers dedicated recirculation kits (DPFB-RECIRCKIT) for the FastBatch™ MultiJet and FastBatch™ DI systems, making tote recirculation simple, safe, and integrated directly into your batching workflow.

What Is Chemical Recirculation?

Chemical recirculation is the process of continuously moving product from the bottom of a tote, through a pump and plumbing loop, and back into the top of the tote. This keeps the chemical in a homogenous solution before and during loading.

This practice is especially important for:

- Suspensions and emulsions

- Products with higher viscosity* (though not all products that are viscous settle out)

- Temperature-sensitive formulations

- Chemicals that settle over time

Why Recirculate Chemicals Before Spraying

1. Prevents Product Settling & Separation

Many crop protection products can settle or stratify when sitting in a tote, especially in cooler temperatures or during extended storage. Recirculation keeps active ingredients evenly suspended, ensuring the chemical entering the sprayer is the same from the first gallon to the last.

2. Improves Application Accuracy

Inconsistent chemical concentration leads to inconsistent application rates. Recirculation ensures the meter sees a uniform product, allowing batching and injection systems to deliver true gallon-for-gallon accuracy.

3. Protects Meters, Valves & Injection Components

Stratified or partially settled product can cause inaccurate readings, valve sticking, or uneven flow. Recirculating reduces spikes in concentration and helps protect system components from unnecessary wear.

4. Reduces Rework, Plugging & Downtime

Uneven product loading can lead to plugged lines, re-sprays, or uneven crop response. Recirculation minimizes these risks by ensuring smooth, predictable flow during every batch.

5. Supports Cold-Weather & Early-Season Spraying

Temperature swings increase viscosity changes and separation. Recirculation stabilizes the product before loading, critical during early spring or late fall application windows.

Introducing Dura Recirculation Kits for FastBatch™ Systems

To support best-in-class chemical handling practices, Dura now offers recirculation kits designed specifically for FastBatch™ MultiJet and FastBatch™ DI systems.

These kits integrate directly into your existing FastBatch setup, without complex plumbing changes or added steps for the operator.

Key Benefits of Dura Recirculation Kits

- 🔄 Continuous tote agitation during batching and loading

- ⚙️ Seamless integration with FastBatch™ MultiJet and FastBatch™ DI

- 💧 Maintains uniform chemical concentration

- 🛠️ Reduces system variability and component wear

- 🧪 Improves batching accuracy across all products

- 🚜 Ideal for sprayers, tenders, and nurse trailers

Designed for Real-World Spraying Operations

Dura recirculation kits are built for practical, field-ready performance. Whether you’re running single-product direct injection or complex multi-product batching, recirculation helps ensure your system performs exactly as designed.

By incorporating recirculation into the FastBatch workflow, operators gain:

- More confidence in every batch

- Less guesswork during mixing

- More consistent field results

The Bottom Line

Recirculating chemicals in the tote isn’t just a best practice, it’s a competitive advantage. It protects your equipment, improves accuracy, and ensures every application starts with a consistent product.

With the introduction of Dura’s FastBatch Recirculation Kits, growers and applicators can now achieve tote recirculation without added complexity, fully integrated into their FastBatch™ MultiJet and FastBatch™ DI systems.

Because when every gallon matters, consistency counts.

Dura Products — Fast. Simple. Safe.™

👉 Learn more about FastBatch systems and recirculation solutions at duraproducts.com

*Note: Check product label for agitation requirements.